Zhou Xiaozhuang, a Young Faculty Member at Our School Publishes Paper Titled Muscle-Inspired Self-Growing Anisotropic Hydrogels with Mechanical Training-Promoting Mechanical Properties in Advanced Materials

ZhouXiaozhuang, a Young Faculty Member at Our School Publishes Paper Titled Muscle-Inspired Self-Growing Anisotropic Hydrogels with Mechanical Training-Promoting Mechanical Properties in Advanced Materials

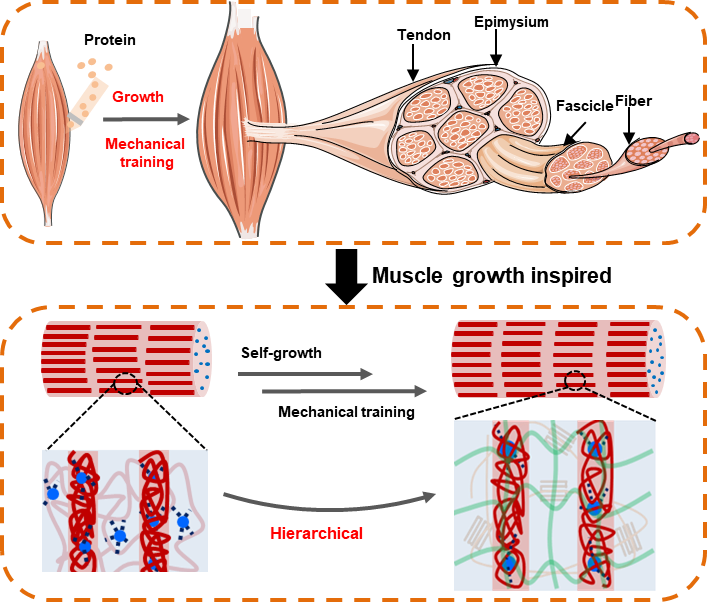

Muscle tissue is one of the toughest anisotropic tissues in the human body. Its exceptional mechanical properties arise from its unique hierarchical fiber structure. The formation of these multi-level fiber structures involves two fundamental biological processes: i) Absorption and conversion of external nutrients; ii) Mechanical training, which transforms the absorbed nutrients into fibrous structures, thereby strengthening and toughening the muscle tissue. Additionally, during muscle growth, existing fiber structures undergo loss and rupture. Subsequent nutrient absorption and mechanical training lead to fiber thickening and reconstruction, resulting in increased muscle size and enhanced load-bearing capacity. Inspired by this natural growth process, researchers have developed mechanical training-promoting fiber structure in-situ generated hydrogel and force promoted self-growing hydrogel. The mechanical properties of all those hydrogels can be enhanced after mechanical training. However, in these hydrogels, the role of force is mainly to generate fiber structure in situ in various isotropic hydrogels (mechanical training promotes structural transformation), or to promote polymerization reaction (mimicking the growth of muscle matrix). Currently, the strategy of simulating muscle growth is still difficult to perfectly replicate the process of muscle growth, i.e., matrix growth and mechanical training-promoting structural transformation.

Addressing this gap, Researcher ZhouXiaozhuang from the School of Chemistry, Chemical Engineering and Life Sciences of Wuhan University of Technology, in collaboration with Prof. CuiJiaxi from the University of Electronic Science and Technology of China, developed a hydrogel system that integrates self-growth with mechanical training. This innovation successfully mimics the muscle growth process, achieving simultaneous size expansion and mechanical enhancement in anisotropic hydrogels. The paper, titled Muscle-Inspired Self-Growing Anisotropic Hydrogels with Mechanical Training-Promoting Mechanical Properties, was recently published in Advanced Materials. XiaYulong, a master’s student at Wuhan University of Technology, is the first author, with Researcher Zhou and Prof. Cui serving as co-corresponding authors.

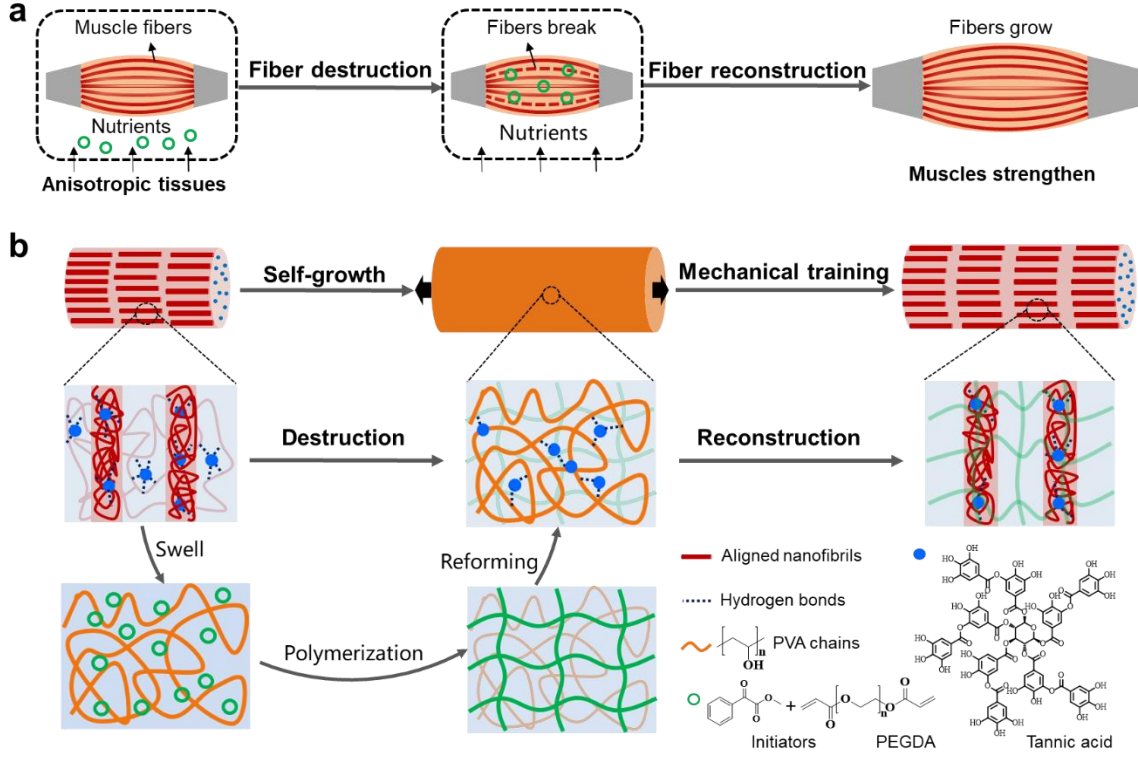

Specifically, in this paper, a self-growth strategy coupled with mechanical training was used to prepare high-toughness anisotropic hydrogels with multi-level structure. For example, the anisotropic supramolecular hydrogel prepared by polyvinyl alcohol (PVA)/tannic acid (TA) (Figure 1) can undergo matrix growth and mechanical training (one growth cycle). Matrix growth includes four steps, which are swelling of nutrients (mixed solution of polyethylene glycol diacrylate (PEGDA), photoinitiator and dimethyl sulfoxide (DMSO)), polymerization of PEGDA, water exchange, and reconstruction of PVA/TA supramolecular network. During the growth process, the fiber structure in anisotropic An-PVA/TA hydrogel was decomposed to form an isotropic hydrogel. The subsequent mechanical training promotes the rearrangement of polymer network, generates hydrogel with anisotropic structure, and completes the structural transformation. After one growth cycle is completed, the next growth cycle can be carried out, which can increase the size of the material (about 2 times) and enhance the mechanical properties of the hydrogel (Young's modulus: from 2.4 MPa to 2.85 MPa; Ultimate tensile strength: from 8.2 MPa to 14.1 MPa; Toughness: from 335 MJ/m3to 465 MJ/m3)

Fig. 1. Mechanical Training Related Growth Design of Tough Anisotropic Hydrogel. Image source: Adv. Mater.

Subsequently, the size, microstructure and composition of anisotropic hydrogel matrix during its growth were systematically studied (Fig. 2). The mechanical training-promoted structural transformation was systematically studied by scanning electron microscope (SEM) and small angle x-ray scattering (SAXS). The results show that the anisotropic hydrogel (An-PVA/TA) can maintain its anisotropic structure while increasing its size after matrix growth and mechanical training-promoted structural transformation. However, the fiber structure of An-PVA-PEGDA hydrogel is different from that of An-PVA/TA hydrogel after growth and training.

Fig. 2. Self-growing Anisotropic Hydrogel. Image source: Adv. Mater.

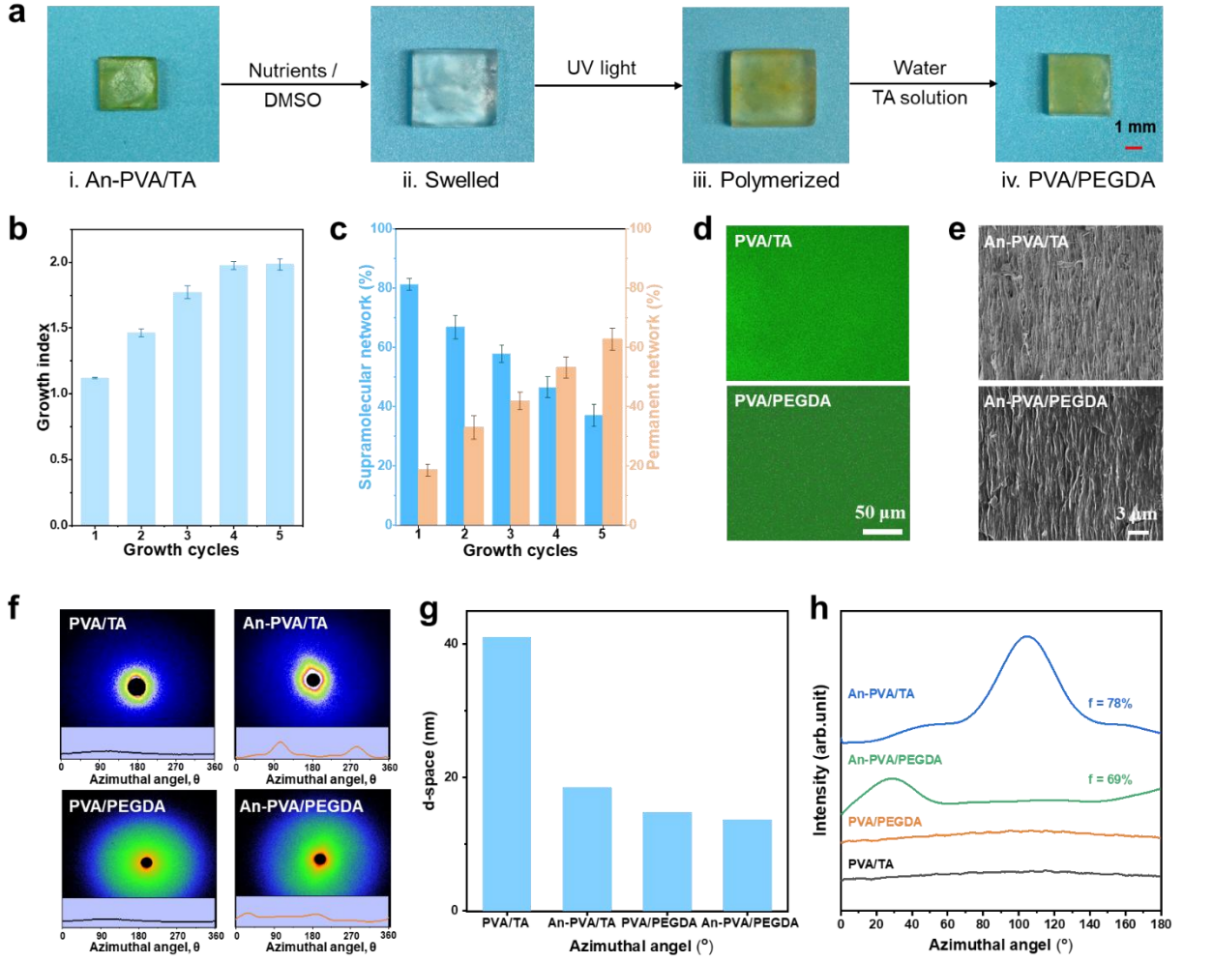

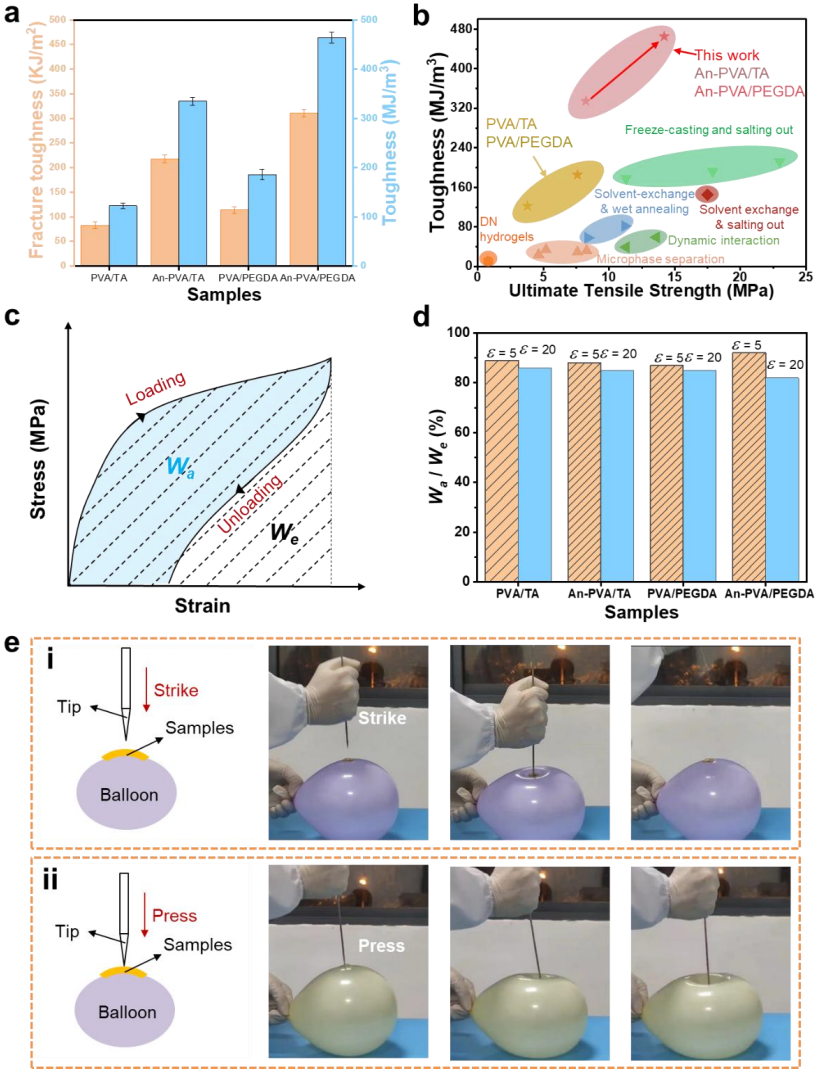

Then, this paper further discusses the mechanism of structural transformation promoted by mechanical training, and tracks the microstructure of hydrogel under different training times. SAXS results show that the orientation structure inside the hydrogel becomes more obvious with the increase of training times (Fig. 3). Subsequently, this paper further studied the aggregation state and mechanical properties of An-PVA/TA hydrogel during growth and mechanical training, and discussed its effect mechanism (Fig. 3). The relationship between microstructure, toughness and fracture toughness of hydrogels is established (Fig. 4), and the maximum tensile strength and fracture toughness of An-PVA/PEGDA hydrogels prepared in this study are compared with those of current tough hydrogels (for example, dual-network microphase separation hydrogels, directional casting and salting-out hydrogels).

Fig. 3. Structural Evolution and Mechanical Properties of Self-Growing Anisotropic Hydrogels. Image source: Adv. Mater.

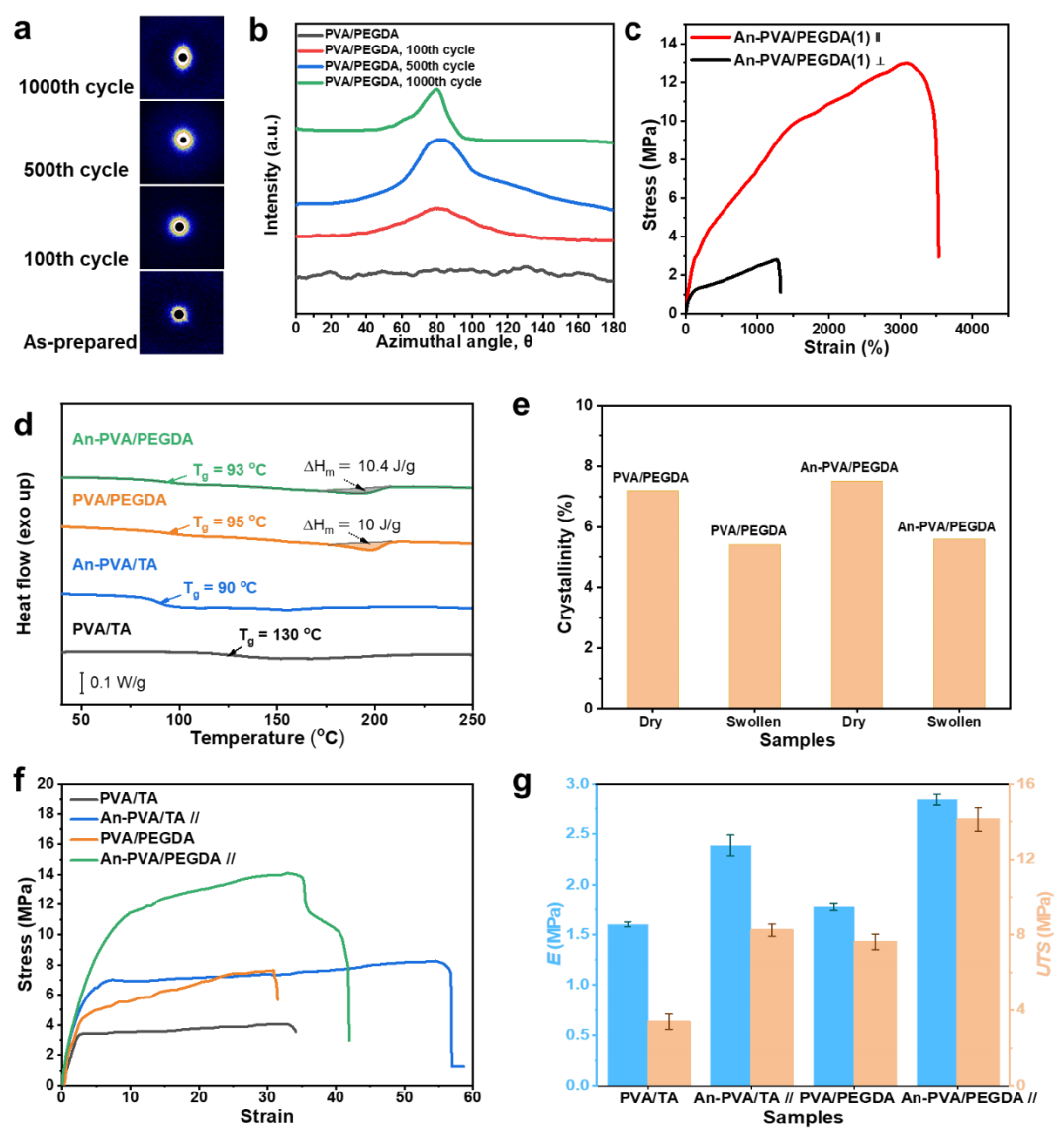

Finally, the energy dissipation capacity of the hydrogels and their application in impact protection were evaluated. The results show that the energy dissipation efficiency of the hydrogels after mechanical training can reach 90% under low strain conditions. Because of their good energy dissipation efficiency, the hydrogels can effectively resist the impact of static force and dynamic force. When the hydrogels are stuck on the surface of the inflatable balloon as a protective material, the balloon can still be inflated without being damaged when it is impacted by a sharp needle (Fig. 4). This also verifies the potential application of the hydrogels as protective materials since they show good impact resistance.

Fig. 4. Evaluation of Ultra-high Energy Consumption Capacity of Hydrogels and Their Application demonstration. Image source: Adv. Mater.

This research is supported by the National Key Research Plan (2021YFB3802300), the Major Project of Basic and Applied Basic Research of Guangdong Province (2021B0301030001), the Joint Fund (8091B022108) and the National Natural Science Foundation (52403153, 55203169, 52171045).

Related links to the paper: https://advanced.onlinelibrary.wiley.com/doi/10.1002/adma.202416744

Brief introduction of Dr. ZhouXiaozhuang:

An ad hoc researcher, the School of Chemistry, Chemical Engineering and Life Sciences, Wuhan University of Technology. In 2020, he graduated from the University of Saarland, Germany, and worked on functional polymer materials in famous universities or scientific research institutions at home and abroad, including Martin Luther University of Halle-Wittenberg, Ohio State University, and Yangtze Delta Region Institute (Huzhou), University of Electronic Science and Technology of China. In December 2024, he joined the School of Chemistry, Chemical Engineering and Life Sciences, Wuhan University of Technology. He mainly engages in the research of organic-inorganic composite materials and bionic composite materials, and has published a total of 27 papers, including 14 papers published as the first author/corresponding author in internationally renowned journals in recent five years, including Nature Communications (2 papers), Advanced Materials (1 paper) and Advanced Functional Materials (2 papers). He has applied for eight patents in China, and two have been authorized.

Contributed by: Han Wei Reviewed by: Li Junsheng